- Home Page

- Company Profile

-

Our Products

- Scaffolding Prop

- Centring And Construction Materials

- Gogo Machin

- wall tie

- Prop Nut

- M S Waller Clamp

- Bridge Shuttering Plate

- Scaffolding Joint Pin

- Cuplock Ledger

- Turn buckle

- WALL FORMWORK

- Earth Compactor

- Scaffolding Frame

- INDUSTRIAL TRUSSES

- Shuttering Plate

- Bottom Adjuster

- Hole Bari

- Tamping Rammer

- Centering Plate

- Mivan Stub Pin

- Scaffolding Single Clip

- Acrow prop

- centring plate

- wire nails

- GOGO MACHIN

- WING NUT

- Mild Steel Rapid Clamp

- Cube Mould

- Scaffolding Gugu Nut

- Scaffolding Gogo Clamp

- Shuttering Clamp

- Slump Cone

- Industrial TIE ROD

- binding wire

- Tie Rod

- Cross Bracings.

- WALKWAY PLANK

- panel puller

- Aluminium Beam Bar

- Concrete Mixer

- Concrete Bucket

- PVC CUBE MOULD

- Stainless Steel C Channels

- Water Stopper

- Bottom Cup

- SCAFFOLDING TIE ROD

- RAPID CLAMP

- Wie Roper

- Scaffolding Span

- Scaffolding Materials and Accessories

- Wire Nails

- Silver Wood

- Plywood

- Structural Steel Products

- Cube Testing Machine

- Binding Wire

- Water Stopper

- Cuplock And Base Jack

- Mild Steel Pipes

- Galvanized Iron Wire

- Scaffolding Accessories

- Wire Roper

- Adjustable Acrow Span

- Adjustable Props Jack

- Arch Shuttering Formwork

- Gogo Machin

- Centring Plate

- Construction Scaffolding System

- H Frame Scaffolding System

- Cross Bracings

- Cuplock Accessories

- H Frame Scaffolding System

- Hollow Jack Nut

- Hot Dipped Galvanized Scaffolding

- long pin 132mm

- M S Waller Clamp

- Mild Steel Round Shuttering Column

- Mivan Pin For Interlocking In Formwork

- Mivan stup pin

- Mivan Wedge Pin

- MS Shikanja

- Rectangular Column Box

- Scaffolding Adjustable Prop Jack

- Scaffolding Base Plate

- Scaffolding Castor Wheel

- Scaffolding Fixed Coupler

- Scaffolding Frame

- Scaffolding Jack Nut

- Scaffolding Pipes

- Scaffolding Props Jack

- Scaffolding Steel Plank

- Scaffolding Vertical

- Sheet Metal Fix Clamp

- Square Column Box

- SS Scaffolding Jack

- Stainless Steel Scaffolding Clamp

- Stub Pin And Wedges

- Swivel Scaffolding Clamp

- Walkway jalli

- WALKWAY PLANK

- WALL FORMWORK

- Wedges & Stub Pins

- Centering Material

- Shuttering Plate

- Construction Equipments

- Telescopic Steel Props

- Prop Nut And Plywood

- Centering And Shuttering Plates

- Tie Rod And Concrete Block

- Wing Nut And Anchor Nut

- Scaffold Joint Pin

- Electrical Handy And Needle Vibrator

- Mivan Stub Pin

- Scaffolding Ledger Blade

- PVC And Block Mould

- Haunch And Wallform Plate

- Concrete Cover Blocks

- View Catalogue

- Contact Us

- Scaffolding Prop

- Centring And Construction Materials

- Scaffolding Span

- Scaffolding Materials and Accessories

- Wire Nails

- Silver Wood

- Plywood

- Structural Steel Products

- Wooden Laminated Sheet

- Cube Testing Machine

- Plywood Flush Door

- Binding Wire

- Water Stopper

- Cuplock And Base Jack

- Mild Steel Pipes

- Galvanized Iron Wire

- Scaffolding Accessories

- Centering Material

- Shuttering Plate

- Construction Equipments

- Telescopic Steel Props

- Prop Nut And Plywood

- Centering And Shuttering Plates

- Tie Rod And Concrete Block

- Wing Nut And Anchor Nut

- Scaffold Joint Pin

- Electrical Handy And Needle Vibrator

- Mivan Stub Pin

- Scaffolding Ledger Blade

- PVC And Block Mould

- Haunch And Wallform Plate

- Concrete Cover Blocks

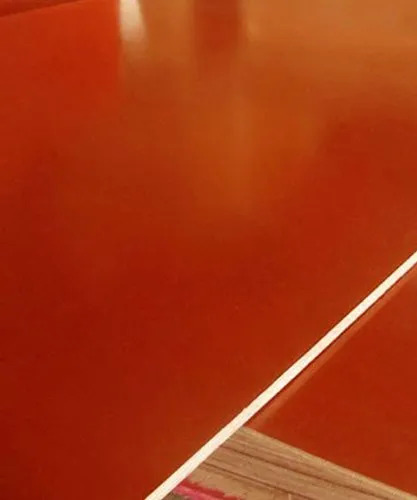

Film Faced Plywood

60 INR/Square Foot

Product Details:

- Size 8 x 4 Feet

- Usage construction

- Feature Strong screw holding, Moisture Proof, Environmental Friendly

- Surface Finish Glossy

- Thickness 18 Millimeter (mm)

- Click to view more

X

Film Faced Plywood Price And Quantity

- 60 INR/Square Foot

- 100 Square Foot

Film Faced Plywood Product Specifications

- Strong screw holding, Moisture Proof, Environmental Friendly

- construction

- 18 Millimeter (mm)

- Glossy

- 8 x 4 Feet

Film Faced Plywood Trade Information

- 1000 Square Foot Per Month

- 7 Days

Product Description

Explore the featured Film Faced Plywood, crafted by elite Indian manufacturers, distributors, suppliers, and traders. Peerless in strength and durability, this hot deal showcases an 8 x 4 feet size with a robust 18 mm thickness. Impeccable moisture-proof qualities and environmental friendliness combine with strong screw-holding ability, making it the preferred choice for outdoor construction projects. Its glossy surface finish ensures an attractive look while delivering functionality. Find the ultimate solution for demanding applications with this unmatched, high-performance plywood.

Primary Competitive Advantages & Application

Film Faced Plywood stands out for its elite durability and impeccable resistance to moisture, delivering peerless performance in outdoor construction scenarios. The primary competitive advantage lies in its strong screw holding feature and environmental sustainability. Typically used on external surfaces in building sites, its glossy finish ensures an attractive appearance and robust utility across floors, walls, and frameworks exposed to the elements.

Packaging, Certifications & Sample Availability

We offer secure packaging options for Film Faced Plywood to ensure goods transport is safe and efficient, no matter the delivery location. Products come with industry-recognized certifications, reinforcing quality assurance standards. Samples are available upon request, allowing clients to evaluate our unmatched quality before placing bulk orders. Our delivery processes accommodate varied timelines and destinations, promising reliable service and satisfaction.

Primary Competitive Advantages & Application

Film Faced Plywood stands out for its elite durability and impeccable resistance to moisture, delivering peerless performance in outdoor construction scenarios. The primary competitive advantage lies in its strong screw holding feature and environmental sustainability. Typically used on external surfaces in building sites, its glossy finish ensures an attractive appearance and robust utility across floors, walls, and frameworks exposed to the elements.

Packaging, Certifications & Sample Availability

We offer secure packaging options for Film Faced Plywood to ensure goods transport is safe and efficient, no matter the delivery location. Products come with industry-recognized certifications, reinforcing quality assurance standards. Samples are available upon request, allowing clients to evaluate our unmatched quality before placing bulk orders. Our delivery processes accommodate varied timelines and destinations, promising reliable service and satisfaction.

FAQs of Film Faced Plywood:

Q: How is Film Faced Plywood used in outdoor construction?

A: Film Faced Plywood is primarily used in outdoor construction for formwork, flooring, and structural applications because it resists moisture and provides strong screw holding abilities, making it ideal for harsh environments.Q: What makes the Film Faced Plywood environmentally friendly?

A: This plywood is manufactured with materials and processes that reduce environmental impact, ensuring sustainability and compliance with eco-friendly standards while maintaining high performance.Q: Where can Film Faced Plywood be applied most effectively?

A: Its most effective application is in areas exposed to weather, such as external floors, walls, scaffolds, and framework in construction projects, where moisture proofing is essential.Q: What is the packaging process for Film Faced Plywood deliveries?

A: Packaging involves robust, moisture-resistant wrapping to safeguard the plywood during transportation, ensuring protection and integrity of goods until delivery at your site.Q: When are samples of Film Faced Plywood available for clients?

A: Samples can be requested prior to purchasing, allowing clients to inspect the quality and certifications before committing to bulk orders.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Prop Nut And Plywood' category

We Are Looking For Business Inquiries Basically From Maharashtra , Karnataka And Goa

Call Me Free

Call Me Free