- Home Page

- Company Profile

-

Our Products

- Scaffolding Prop

- Centring And Construction Materials

- Bridge Shuttering Plate

- Acrow prop

- Hole Bari

- Wall Tie

- M S Waller Clamp

- wire nails

- Scaffolding Joint Pin

- Gogo Machin

- centring plate

- Scaffolding Single Clip

- Shuttering Plate

- Cuplock Ledger

- GOGO MACHIN

- Bottom Adjuster

- Prop Nut

- Tamping Rammer

- Centering Plate

- Mivan Stub Pin

- Earth Compactor

- Scaffolding Frame

- INDUSTRIAL TRUSSES

- WALL FORMWORK

- Turn buckle

- WING NUT

- Mild Steel Rapid Clamp

- Cube Mould

- Scaffolding Gugu Nut

- Scaffolding Gogo Clamp

- Shuttering Clamp

- Slump Cone

- Industrial TIE ROD

- binding wire

- Tie Rod

- Cross Bracings.

- WALKWAY PLANK

- panel puller

- Aluminium Beam Bar

- Concrete Mixer

- Concrete Bucket

- PVC CUBE MOULD

- Stainless Steel C Channels

- Water Stopper

- Bottom Cup

- SCAFFOLDING TIE ROD

- RAPID CLAMP

- Wie Roper

- Scaffolding Span

- Scaffolding Materials and Accessories

- Wire Nails

- Silver Wood

- Structural Steel Products

- Cube Testing Machine

- Binding Wire

- Water Stopper

- Cuplock And Base Jack

- Mild Steel Pipes

- Galvanized Iron Wire

- Scaffolding Accessories

- Wire Roper

- Adjustable Acrow Span

- Adjustable Props Jack

- Arch Shuttering Formwork

- Gogo Machin

- Centring Plate

- H Frame Scaffolding System

- Construction Scaffolding System

- Cross Bracings

- Cuplock Accessories

- H Frame Scaffolding System

- Hollow Jack Nut

- Hot Dipped Galvanized Scaffolding

- long pin 132mm

- M S Waller Clamp

- Mild Steel Round Shuttering Column

- Mivan Pin For Interlocking In Formwork

- Mivan stup pin

- Mivan Wedge Pin

- MS Shikanja

- Rectangular Column Box

- Scaffolding Adjustable Prop Jack

- Scaffolding Base Plate

- Scaffolding Castor Wheel

- Scaffolding Fixed Coupler

- Scaffolding Frame

- Scaffolding Jack Nut

- Scaffolding Pipes

- Scaffolding Props Jack

- Scaffolding Steel Plank

- Scaffolding Vertical

- Sheet Metal Fix Clamp

- Square Column Box

- SS Scaffolding Jack

- Stainless Steel Scaffolding Clamp

- Stub Pin And Wedges

- Swivel Scaffolding Clamp

- Walkway jalli

- WALKWAY PLANK

- WALL FORMWORK

- Wedges & Stub Pins

- Centering Material

- Shuttering Plate

- Construction Equipments

- Telescopic Steel Props

- Centering And Shuttering Plates

- Tie Rod And Concrete Block

- Wing Nut And Anchor Nut

- Scaffold Joint Pin

- Electrical Handy And Needle Vibrator

- Mivan Stub Pin

- Scaffolding Ledger Blade

- PVC And Block Mould

- Haunch And Wallform Plate

- Concrete Cover Blocks

- View Catalogue

- Contact Us

- Scaffolding Prop

- Centring And Construction Materials

- Scaffolding Span

- Scaffolding Materials and Accessories

- Wire Nails

- Silver Wood

- Structural Steel Products

- Cube Testing Machine

- Binding Wire

- Water Stopper

- Cuplock And Base Jack

- Mild Steel Pipes

- Galvanized Iron Wire

- Scaffolding Accessories

- Centering Material

- Shuttering Plate

- Construction Equipments

- Telescopic Steel Props

- Centering And Shuttering Plates

- Tie Rod And Concrete Block

- Wing Nut And Anchor Nut

- Scaffold Joint Pin

- Electrical Handy And Needle Vibrator

- Mivan Stub Pin

- Scaffolding Ledger Blade

- PVC And Block Mould

- Haunch And Wallform Plate

- Concrete Cover Blocks

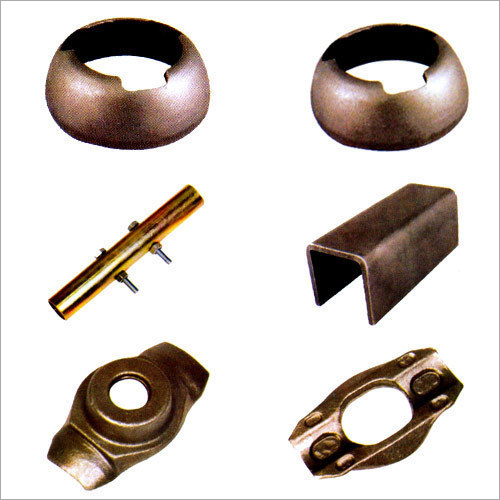

Adjustable Base Jack

MOQ : 5 Pieces

Adjustable Base Jack Specification

- Prop Head

- Base Head

- Technique

- Forged

- Pin

- Integrated Locking Pin

- Sleeve size

- 36 mm to 40 mm

- Features

- Adjustable Height, High Strength, Corrosion Resistant

- Color

- Silver/Grey

- Constitute

- Steel Tube & Base Plate

- Weight

- 2.5 kg

- Product Type

- Scaffolding Props

- Material

- Steel

- Components

- Base Plate, Threaded Rod, Nut, Jack

- Diameter

- 36 mm

- Width

- 150 mm (Base Plate)

- Length

- 600 mm

- Height

- Adjustable up to 600 mm

- Thickness

- 5 mm (Base Plate)

- Platform Loading Capacity

- 2 Tons

- Surface Treatment

- Pre-Galvanized

- Application

- Construction

- Size

- 36 mm x 600 mm

Adjustable Base Jack Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Adjustable Base Jack

Our offered Adjustable Base Jack is available in different sizes and other specifications, which is highly demanded in market due to their unique features like high tensile strength and seamless finish. These base jacks are made under the guidance of our expert professionals by using latest technologies keeping in mind the set quality norms. Further, Adjustable Base Jack is checked by our quality controller on different quality parameters before delivering to our valued customer end.

Product Details:

|

Color |

Blue |

|

Dimension |

38*600 |

Unmatched Durability and Grip

With its corrugated base plate and forged steel construction, the Adjustable Base Jack ensures stability on uneven surfaces, reducing the risk of slippage and improving safety. The heavy-duty jack nut and welded ends enhance product longevity, making it a dependable choice for repeated construction use.

Flexible Adjustment for Multiple Applications

This jacks wide adjustment range (100 mm to 600 mm) allows for precise elevation of scaffolding and formwork, accommodating varying site levels and requirements. Its design ensures reliability under different construction scenarios, adapting seamlessly to both minor and major adjustments.

FAQs of Adjustable Base Jack:

Q: How is the Adjustable Base Jack installed at a construction site?

A: Installation involves positioning the corrugated base plate on a stable surface, then adjusting the height using the Acme threaded rod and the cast steel jack nut. Welded ends provide a secure fit, and pre-galvanized surfaces protect against rust during setup.Q: What makes the corrugated base plate beneficial for formwork support?

A: The corrugated base plate enhances grip on surfaces, reducing movement and providing firm foundation support for scaffolding and formwork, especially on uneven or slippery ground.Q: Where is this Adjustable Base Jack manufactured and supplied from?

A: This product is forged and processed in India and supplied either in gunny bags or bundles for convenient handling and onsite usage.Q: When should corrosion-resistant jacks be used in construction?

A: Corrosion-resistant jacks are ideal for environments exposed to moisture, chemicals, or prolonged outdoor use, ensuring longer product life and structural integrity under harsh site conditions.Q: What process ensures the jacks durability against environmental wear?

A: The jack undergoes forging and pre-galvanization during manufacturing, coupled with welded ends and the use of cast steel for the nut, providing excellent resistance to corrosion and physical wear.Q: How does using an Acme thread improve adjustment and stability?

A: The Acme thread design offers smooth, precise height adjustments and distributes load evenly, resulting in enhanced stability and safety during scaffolding or formwork setup.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Scaffolding Materials and Accessories Category

Concrete Cover Block

Price 250 INR / Box

Minimum Order Quantity : 1 Box

Surface Treatment : Powder Coating

Application : Construction

Components : Other

Material : Other , High Grade Concrete

Cup Lock System

Price 73 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Surface Treatment : Other

Application : Other, Construction and Infrastructure

Components : Other

Material : Steel

Construction Trolley

Price 2400 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other

Application : Other, Construction and material transportation

Components : Other

Material : Steel

Cup Lock Accessories

Price 60 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, Galvanized or painted for corrosion resistance

Application : Other, Construction scaffolding systems

Components : Other

Material : Other

We Are Looking For Business Inquiries Basically From Maharashtra , Karnataka And Goa

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free