- Home Page

- Company Profile

-

Our Products

- Scaffolding Prop

- Centring And Construction Materials

- Scaffolding Single Clip

- Cuplock Ledger

- Bottom Adjuster

- Hole Bari

- Centering Plate

- WALL FORMWORK

- Shuttering Plate

- Earth Compactor

- Bridge Shuttering Plate

- Scaffolding Joint Pin

- M S Waller Clamp

- Tamping Rammer

- centring plate

- INDUSTRIAL TRUSSES

- Prop Nut

- GOGO MACHIN

- Mivan Stub Pin

- Turn buckle

- Scaffolding Frame

- Acrow prop

- WING NUT

- wire nails

- Wall Tie

- Gogo Machin

- Mild Steel Rapid Clamp

- Cube Mould

- Scaffolding Gugu Nut

- Scaffolding Gogo Clamp

- Shuttering Clamp

- Slump Cone

- Industrial TIE ROD

- binding wire

- Tie Rod

- Cross Bracings.

- WALKWAY PLANK

- panel puller

- Aluminium Beam Bar

- Concrete Mixer

- Concrete Bucket

- PVC CUBE MOULD

- Stainless Steel C Channels

- Water Stopper

- Bottom Cup

- SCAFFOLDING TIE ROD

- RAPID CLAMP

- Wie Roper

- Scaffolding Span

- Scaffolding Materials and Accessories

- Wire Nails

- Silver Wood

- Structural Steel Products

- Cube Testing Machine

- Binding Wire

- Water Stopper

- Cuplock And Base Jack

- Mild Steel Pipes

- Galvanized Iron Wire

- Scaffolding Accessories

- Wire Roper

- Adjustable Acrow Span

- Adjustable Props Jack

- Arch Shuttering Formwork

- Gogo Machin

- Centring Plate

- H Frame Scaffolding System

- Construction Scaffolding System

- Cross Bracings

- Cuplock Accessories

- H Frame Scaffolding System

- Hollow Jack Nut

- Hot Dipped Galvanized Scaffolding

- long pin 132mm

- M S Waller Clamp

- Mild Steel Round Shuttering Column

- Mivan Pin For Interlocking In Formwork

- Mivan stup pin

- Mivan Wedge Pin

- MS Shikanja

- Rectangular Column Box

- Scaffolding Adjustable Prop Jack

- Scaffolding Base Plate

- Scaffolding Castor Wheel

- Scaffolding Fixed Coupler

- Scaffolding Frame

- Scaffolding Jack Nut

- Scaffolding Pipes

- Scaffolding Props Jack

- Scaffolding Steel Plank

- Scaffolding Vertical

- Sheet Metal Fix Clamp

- Square Column Box

- SS Scaffolding Jack

- Stainless Steel Scaffolding Clamp

- Stub Pin And Wedges

- Swivel Scaffolding Clamp

- Walkway jalli

- WALKWAY PLANK

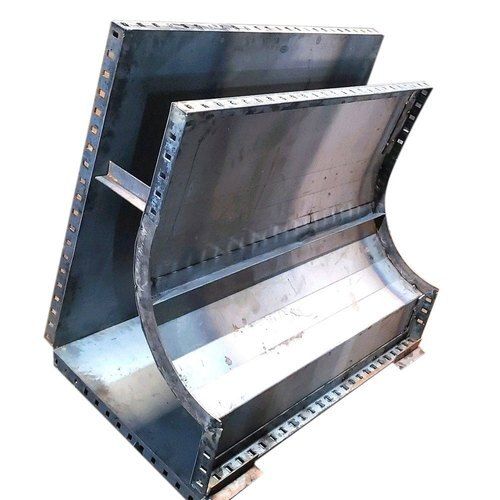

- WALL FORMWORK

- Wedges & Stub Pins

- Centering Material

- Shuttering Plate

- Construction Equipments

- Telescopic Steel Props

- Centering And Shuttering Plates

- Tie Rod And Concrete Block

- Wing Nut And Anchor Nut

- Scaffold Joint Pin

- Electrical Handy And Needle Vibrator

- Mivan Stub Pin

- Scaffolding Ledger Blade

- PVC And Block Mould

- Haunch And Wallform Plate

- Concrete Cover Blocks

- View Catalogue

- Contact Us

- Scaffolding Prop

- Centring And Construction Materials

- Scaffolding Span

- Scaffolding Materials and Accessories

- Wire Nails

- Silver Wood

- Structural Steel Products

- Cube Testing Machine

- Binding Wire

- Water Stopper

- Cuplock And Base Jack

- Mild Steel Pipes

- Galvanized Iron Wire

- Scaffolding Accessories

- Centering Material

- Shuttering Plate

- Construction Equipments

- Telescopic Steel Props

- Centering And Shuttering Plates

- Tie Rod And Concrete Block

- Wing Nut And Anchor Nut

- Scaffold Joint Pin

- Electrical Handy And Needle Vibrator

- Mivan Stub Pin

- Scaffolding Ledger Blade

- PVC And Block Mould

- Haunch And Wallform Plate

- Concrete Cover Blocks

binding wire

Price 62 INR/ Kilograms

MOQ : 1 Kiloampere

binding wire Specification

- Purity

- High purity

- Form

- Wire

- Material Grade

- Low carbon steel

- Installation Type

- Manual

- Usage

- Tying and binding in construction agriculture and industrial applications

- Application

- Construction and Binding

- Features

- Corrosion-resistant

- Product Type

- Binding Wire

- Main Material

- Steel

- Surface Treatment

- Galvanized

- Size

- Standard and custom sizes

- Feature

- Durable and flexible

- Shape

- Round

About binding wire

Experience the in-demand binding wire that stands out for its superlative durability and unrivaled flexibility. Crafted from high-purity, low carbon steel, our matchless round binding wire features a first-class galvanized surface for exceptional corrosion resistance. Whether you need standard or custom sizes, this wire is the preferred choice for construction, agricultural, and industrial applications. Unlock seamless tying and binding processes with our premium manual installation wirea top-tier offering from trusted distributors, manufacturers, suppliers, and traders across India.

Binding Wire: Versatile Use and Application

Binding wire is a staple in the construction, agriculture, and industrial sectors, highly valued for tying and securing materials. Commonly used by builders, contractors, and tradespeople, it is applied manually to bundle rods, reinforce structures, and bind various components effectively. The wires round shape and flexibility ensure ease of use, while its high-purity, galvanized steel enhances lasting performance in demanding environments.

Export Market, Quick Supplies, and Domestic Reach

With a strong presence in major export markets and robust domestic supply, our binding wire boasts quick dispatch and efficient shipment options. Clients benefit from consistent supply ability, covering both international and Indian markets. Leading manufacturers and distributors ensure prompt delivery, meeting the urgent needs of construction, agricultural, and industrial clientele throughout the region and beyond.

Binding Wire: Versatile Use and Application

Binding wire is a staple in the construction, agriculture, and industrial sectors, highly valued for tying and securing materials. Commonly used by builders, contractors, and tradespeople, it is applied manually to bundle rods, reinforce structures, and bind various components effectively. The wires round shape and flexibility ensure ease of use, while its high-purity, galvanized steel enhances lasting performance in demanding environments.

Export Market, Quick Supplies, and Domestic Reach

With a strong presence in major export markets and robust domestic supply, our binding wire boasts quick dispatch and efficient shipment options. Clients benefit from consistent supply ability, covering both international and Indian markets. Leading manufacturers and distributors ensure prompt delivery, meeting the urgent needs of construction, agricultural, and industrial clientele throughout the region and beyond.

FAQs of binding wire:

Q: How is the binding wire typically installed in construction projects?

A: Binding wire is generally installed manually by workers, who use pliers to tie and secure rebars, rods, or other structural elements, ensuring firm and safe assemblies.Q: What makes this binding wire corrosion-resistant?

A: The binding wire undergoes a galvanized surface treatment, providing a protective zinc coating that prevents rust and corrosion, making it suitable for harsh working conditions.Q: When should I opt for custom sizes over standard binding wire?

A: Custom sizes are recommended when project specifications require wires of particular diameters or lengths to achieve exact tying or binding requirements in non-standard applications.Q: Where is this binding wire mainly supplied from and to?

A: Our binding wire is primarily supplied by leading manufacturers and distributors across India, serving both domestic clients and major export markets worldwide.Q: What are the primary benefits of using high-purity low carbon steel binding wire?

A: High-purity low carbon steel binding wire offers enhanced ductility, easy handling, excellent strength, and long-lasting durability, especially needed in construction and industrial environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Centring And Construction Materials Category

WING NUT

Price 26 INR / Number

Minimum Order Quantity : 1 Number

Surface Treatment : Zinc plated for corrosion resistance

Product Type : Fasteners

Size : Standard sizes available

Usage : Used in various fastening applications

Acrow prop

Price 72 INR / Number

Minimum Order Quantity : 1 Number

Surface Treatment : Painted or galvanized

Product Type : Adjustable Acrow Prop

Size : Various lengths adjustable

Usage : Scaffolding and construction support

Bridge Shuttering Plate

Price 80 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Surface Treatment : Coated

Product Type : Bridge Shuttering Plate

Size : Standard

Mild Steel Rapid Clamp

Price 38 INR / Number

Minimum Order Quantity : 1 Number

Surface Treatment : Rust Proof

Product Type : Rapid Clamp

Size : 8mm

Usage : Construction

We Are Looking For Business Inquiries Basically From Maharashtra , Karnataka And Goa

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free